Blog

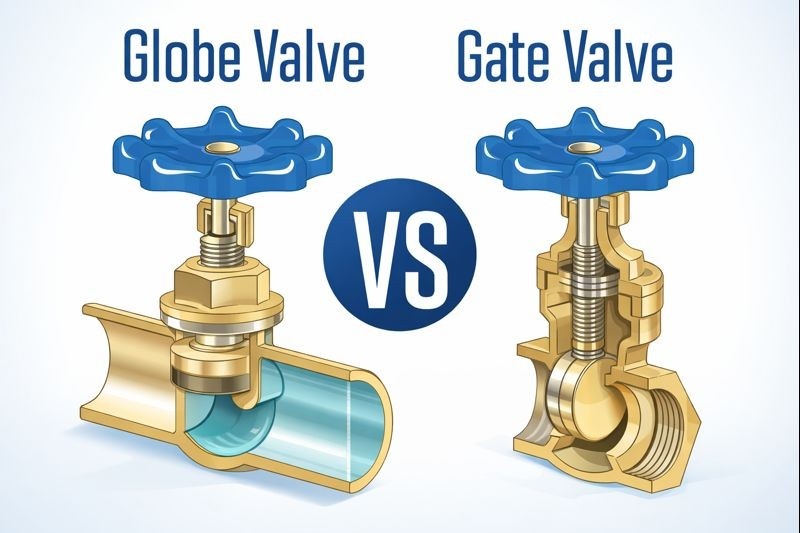

Differences Between Gate Valves and Globe Valves

Valves are critical components in industrial fluid systems, ensuring proper flow control, system safety, and operational efficiency. Among the many types of valves, gate valves and globe valves are commonly used but serve different purposes.

Understanding the differences between gate valves and globe valves is essential for engineers, operators, and maintenance professionals to make informed choices that maximize performance and reduce operational costs.

In this article, we’ll explore the structure, working mechanisms, features, applications, and selection criteria for both valve types, helping you choose the right valve for your system.

1. Overview of Gate Valves

Gate valves belong to the linear motion valve family and are primarily used for on/off flow control. They consist of a wedge-shaped disc (gate) that moves perpendicular to the flow path.

Key Features of Gate Valves:

- Full Bore Flow: Minimal obstruction when fully open → very low pressure drop.

- Construction: Simple, with most internal components at the top; stem can be rising or non-rising.

- Operation: Best used in fully open or fully closed positions; not suitable for throttling.

- Applications: Water supply, fire protection lines, oil & gas pipelines, high-flow industrial systems.

- Advantages: Bidirectional, energy-efficient, long-lasting, low maintenance.

Pro Tip: Knife gate valves are ideal for slurry or viscous fluids, cutting through solids to maintain flow.

2. Overview of Globe Valves

Globe valves are designed for flow regulation (throttling) as well as isolation. They have a spherical body with an internal disc or plug that moves parallel to the flow.

Key Features of Globe Valves:

- Flow Control: Excellent for precise flow adjustment; proportional to disc movement.

- Construction: Complex; many components inside the cavity; rising stem design.

- Operation: Can throttle flow efficiently; unidirectional.

- Applications: Steam systems, chemical processes, HVAC circuits, laboratory lines.

- Advantages: Reliable sealing, high durability, precise control.

- Limitation: Higher pressure drop due to flow path changes; requires more energy to operate.

Pro Tip: Use globe valves for sensitive systems where precise flow or pressure regulation is critical.

3. Gate Valve vs Globe Valve – Side-by-Side Comparison

| Feature | Gate Valve | Globe Valve |

|---|---|---|

| Primary Function | Isolation (On/Off) | Flow regulation and isolation |

| Flow Path | Straight, full bore | Curved, changes direction |

| Pressure Drop | Very low | High (due to flow resistance) |

| Flow Control | Not suitable for throttling | Excellent for throttling |

| Directionality | Bidirectional | Unidirectional |

| Operating Mechanism | Disc moves perpendicular to flow | Disc moves parallel to flow |

| Maintenance | Simple, fewer moving parts | Complex, more frequent checks |

| Applications | Water lines, fire protection, pipelines | Steam lines, chemical plants, HVAC |

| Energy Efficiency | High | Moderate (higher resistance) |

4. Working Mechanism

Gate Valve Working:

- The Disc moves upwards to open, downwards to close.

- Full flow or complete shutoff only.

- Linear motion creates minimal turbulence.

Globe Valve Working:

- The Disc moves parallel to flow, adjusting the passage area.

- Allows precise flow control with tight sealing.

- Flow resistance is higher → noticeable pressure drop.

5. Pressure Drop & Flow Control Considerations

- Gate Valve: Ideal for pipelines requiring low energy loss. Can handle large diameter pipes efficiently.

- Globe Valve: Suitable for systems needing frequent adjustment. The flow path change increases pressure drop but ensures accurate throttling.

Tip: Never use gate valves for throttling; it damages the disc and reduces valve life.

6. Installation & Maintenance

- Gate Valve: Easier to install, fewer internal components, less frequent maintenance.

- Globe Valve: Must follow flow direction markings; more moving parts → regular maintenance recommended.

7. Choosing the Right Valve

Factors to Consider:

- Flow Conditions: Slurry? High-pressure fluid? Low-pressure drop required?

- Control Needs: Is throttling needed or just full shutoff?

- Operating Environment: Temperature, pressure, corrosive fluids.

- Installation Space: Gate valves may require more vertical space; globe valves more horizontal clearance.

- Cost vs Lifecycle: Gate valves cheaper initially; globe valves offer better reliability and long-term performance.

Quick Rule:

- Gate Valve → On/Off, high flow, low pressure drop.

- Globe Valve → Precise control, throttling, sensitive systems.

AI Overview

Discover the key differences between gate valves and globe valves, including structure, flow control, pressure drop, and applications, to choose the right valve for efficient industrial systems.

FAQs

What is the key difference between a gate valve and a globe valve?

Gate valves are designed for on/off flow control with minimal pressure drop, while globe valves provide precise flow regulation and throttling.

Can gate valves be used for throttling applications?

No. Using a gate valve partially open can cause vibration and damage. For throttling, always use a globe valve.

Which valve type is more energy-efficient?

Gate valves are more energy-efficient because their straight-through flow reduces pump power and pressure loss.

Are globe valves bidirectional like gate valves?

No. Globe valves are unidirectional and must follow the flow direction marked on the valve body for proper operation.

How do I choose between a gate valve and a globe valve?

Consider flow rate, pressure drop, throttling needs, and operating environment. Use gate valves for on/off high-flow systems and globe valves for precise flow control.

Conclusion

Both gate valves and globe valves are vital in industrial fluid systems, but their design, functionality, and applications differ significantly. Understanding these differences ensures proper valve selection, reduces maintenance costs, improves efficiency, and prevents system failures.

If you need high-quality marine valves & flow control solutions for your industrial system, contact K. Hashim today. Our experts will guide you to the right solution for your flow control needs.

Explore More Expert Insights

Discover deck & engine components, marine epoxies, fasteners, fittings, flanges, valves, and gauges for your next project.

–Different Types of Buttweld Fittings and Their Applications – Explore Buttweld Fittings: Types and Practical Applications

–Importance of Expansion Joints in Building Construction –Importance of Expansion Joints in Building Construction

–Personal Protective Equipment (PPE) Compliance Checklist –Ensure Safety with PPE Compliance Checklist

–Uses of Woolen Felt Sheets in Industrial Applications – Woolen Felt Sheets Uses and Sounding Cock Valves

–Common Mistakes While Operating Deck Machinery Systems – Operating Deck Machinery Systems: Mistakes to Avoid